MILD STEEL FIREPOT DRAWINGS

FABRICATING SUGGESTIONS

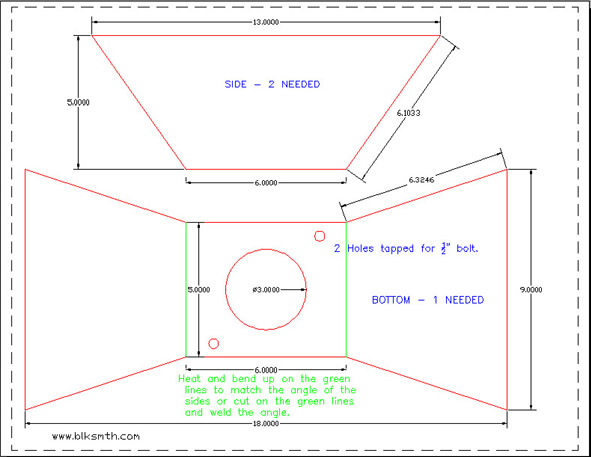

This firepot is the same as on ”my portable forge”. It is about the same size as the Centaur Vulcan Firepot (9 inche by 13 inch top opening), except it is 4 1/2 inches deep (deeper than the Centaur pot). It can be made of 1/4 inch plate or heavier as desired. The last one I made was made with the 2 sides of 5/8 inch plate and the bottom was 3/8” plate. The bottom and ends do not seem to deteriorate as quickly as the sides (at least that is my experience with the blower etc. that I use). I do not know how long a mild steel firepot will last compared to a good 3/4 inch thick cast iron firepot. I do know that mild steel melts at a much higher temperature than does cast iron, but for some reason cast iron works well for castings that get extremely hot and cold such as firepots, stoves, etc. If a mild steel firepot deteriorates for some reason, a new piece of mild steel can be welded in to replace the deteriorated metal - that can not be easily done with cast iron.

These drawings do not include the air intake piping which can be seen on ”my portable forge”. The air intake piping is lightweight 3 inch round or square. Square is easier to fabricate. Note that the vertical pipe slants toward the fan. That slant helps keep the ash etc. that falls through the clinker breaker from getting into the fan. A weighted pivoting ash dump also needs to be fabricated for the bottom of the vertical air intake pipe.

These drawings do not include a 1/4 inch by 2 inch flat mild steel rim welded around the top which allows the firepot to set into the forge table opening without falling through. Since firepots expand and contract depending on their temperature, I usually do not fasten the firepot other than to the air inlet piping.

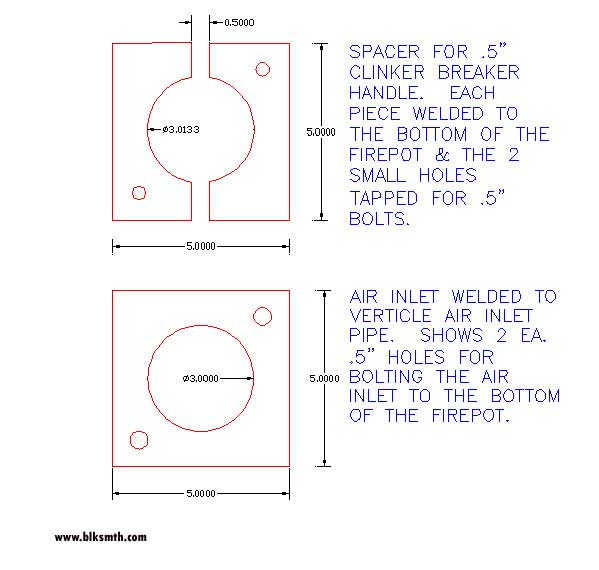

These drawings do not include clinker breaker specifications (see pictures below of a www.centaurforge.com/ clinker Breaker). The clinker breaker design is up to the maker, but can be as simple as a mild steel circle approx. 2 1/2 inches in diameter welded on top of a 1/2 inch round handle.

DIMENSIONS ARE IN INCHES

Pictures showing Clinker Breaker in Center of Firepot

The clinker breaker has a 1/2 inch hole drilled horizontally through it for the 1/2” rod/handle. It is held in place by a bolt tapped into the side of the clinker breaker.

Bottom picture shows the clinker breaker in a turned position. Normally it has a flat side up shown in the top picture. The clinker breaker pivots on a 1/2 inch rod that has a turned down end to serve as a handle. The handle is on the outside of the forge so it can be reached. Bolt holding clinker breaker to 1/2” rod/handle is on the third flat side of the breaker (not seen in picture).